How To Build The King Of DIY Fly Traps

I found this open source article for plans to a fly trap. One of the pictures shows it packed full of flies. Think of what a great source of food this could be for your chickens. I haven’t tried it yet, but I thought I’d share.

Description

This section is from the book “Shop Projects Based On Community Problems“, by Myron G. Burton. Also available from Amazon:Shop Projects Based on Community Problems.

Fly Trap

Materials

Basswood(Chap. III., Par. 31).

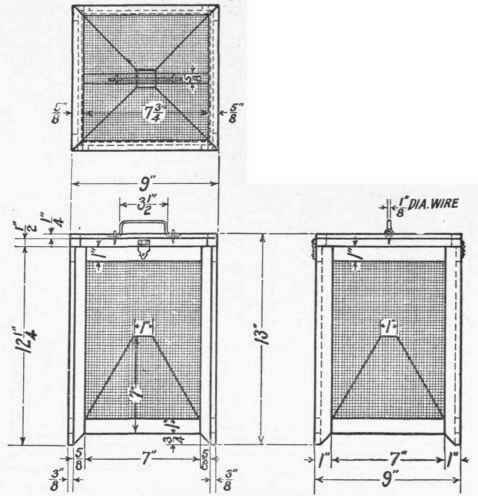

8 pcs. 3/8″xl”xl2 1/2″ S 2 SSides. 8 pcs. 3/8″xl”x 7 1/2″ S 2 SCross pieces. 5 pcs. 1/2″x3/4″x9″ S 2 S Top pes.

8 pes. 1/4″x3/4″x9″ S 2 STrim. 3 dozen 1″ brads.

3 dozen 1/2″ brads.

1 1/2 dozen 3/8″ corrugatednails.

1 yard 24″ screen wire.

9 dozen small tacks.

1 piece 5/32″ Bessemer rod 8″ long.

2 screw eyes No. 114.

1 pair 3/4″x3/4″ brass hinges. 1 small clasp.

Introductory Statement

Recent investigation has proven that the common housefly is a very dangerous enemy to human life. The fact that it spreads disease and is in every way undesirable is sufficient reason why everybody should be as careful as possible to prevent its increase. One of the most successful ways to wage war on flies is to screen our homes so as to shut them out, and then leave no uncovered garbage pails or any other feeding places for them.

In cities where everybody has been interested in disposing of flies the results have been very encouraging. School children have helped wonderfully by engaging in fly-catching contests.

You can do a great practical good for your own home and community by making this flytrap carefully and using it throughout the fly season.

References:

The House Fly as Disease Carrier, L. O. Howard. Published by F. A.

Stokes Pub. Co., New York. U. S. Bulletin No. 459, and U. S. Bulletin No. 679, House Flies. Insects and Disease, Doane. Henry Holt & Co. Our Household Insects, Butler. Longmans, Green Co. Household Insects and Methods of Control, Bulletin No. 3, Ithaca, N. Y. U. S. Bulletin No. 155, How Insects Affect Health. Fly Traps and Literature. International Harvester Co., Chicago. Winter War on Flies, Willard Price, Technical World, February, 1915. Our Insect Friends and Enemies, John Smith. J. B. Lippincott Pub. Co.

Fly Trap

You will probably have to rip your material from stock; select the best surface of your stock for a working face (Chapter II., Paragraph 2); plane one edge for a working edge (Chapter II., Paragraph 4). With the marking gauge, gauge the width of the strips on both surfaces of the stock (Chapter II., Paragraph 6). Rip just outside the line; plane to the gauge lines. Prepare all the side strips in like manner. Saw them the required length. Notice that on two sides of the fly trap, the side strips are narrower than on the other two sides. This is done so the four sides will be equal when assembled. Miter the lower end of each strip, as shown in the drawing.

The Side Cross Rails

Rip out and plane the side cross rails in the same manner in which you have made the side strips. Cut all these rails the required length, as shown in the drawing. They may be easily and accurately sawed in the square cut of a miter box.

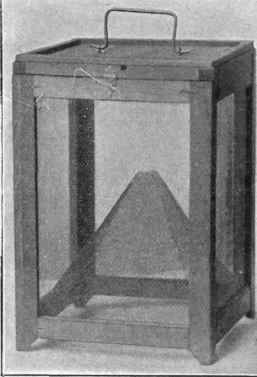

Assembling The Body Of The Trap

Each side is merely a rectangular frame. Lay two side strips flat on your bench top with the two cross rails in such position as to form a frame; make the angles square and fasten with corrugated nails (Chapter II., Paragraph 23). Assemble all sides in like manner. Cut screen wire the proper size and cover the inside of each frame; fasten the screen wire in position with small tacks. Assemble the four frames box fashion; they should be joined with a plain butt joint(Chapter II., Paragraph 60) at each corner; fasten with brads (Chapter II., Paragraph 21).

The Lid

The lid is a square frame (with a cross bar in the middle for the handle ) joined at the corners with plain butt joints (Chapter V., Paragraph 60), fastened with brads. Square the stock for the lid (Chapter II., Paragraphs 1, 2, 3 and 4); cut each piece the required dimensions; assemble as explained; cover with screen wire. Strips of wood 1/4″ thick are to be used as a trim on the lid, to cover the tacks and add to the appearance of the work; miter this trim at each corner (Chapter V., Paragraph 64); fasten it on with brads.

The Inside Wire Pyramid

In order to cut the screen wire for this piece you should make a pattern of paper; if you will draw four triangles (each of the size of one side, as shown in the drawing) adjoining each other, you will have a correct pattern. Allow about an inch to make the lap; bend into proper shape; with a piece of the wire weave the open corner securely together; place in position and fasten with tacks. These tacks may also be covered with a trim just as you did the lid.

The Handle

Bend the wire to form the handle; attach with two screw eyes. Fasten the lid in position with two small hinges and put on the fastening. Plane off uneven places if there are any. Stain some dark color (Chapter IV., Paragraph 54).

Optional and Home Projects Employing Similar Principles.

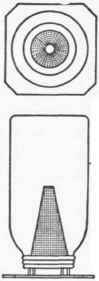

1. A very satisfactory and convenient fly trap may be made of any ordinary glass fruit jar, as shown in the Suggestions. The entire central portion of the lid is cut out. A slender cone is made of screen wire with a small opening at the point. This cone may be attached to the lid by having a number of small holes punched around the opening in the lid, through which a small wire can be so woven as to bind the cone securely. A thin piece of wood, with four tacks or small nails, so driven as to extend slightly above the surface, will make a satisfactory base. In a trap of this kind the flies may be easily killed by pouring in boiling water.

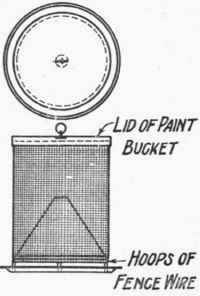

2. An all-metal fly trap can be made from the lid of an old paint bucket, a few scraps of heavy fence wire and a piece of screen wire. The screen wire is rolled into a cylinder just as large as the bucket lid, which is to form the top. The screen wire cylinder is woven to the rim of the lid through small holes, as indicated in the drawing. A hoop of fence wire of the same diameter as the lid is attached to the other end of the cylinder, to hold it in shape. The inside cone of screen wire is attached to a second hoop of the same size as the first. The cone is placed in position, and if properly made will fit so closely that it will not require fastening. Small pieces of wire may be attached to form legs about a half-inch long. A sheet of tin, or an old pie tin will answer for a base.

Home and Gardening Ideas At home and Gardening ideas we believe inspiring readers about homesteading, self sufficiency

Home and Gardening Ideas At home and Gardening ideas we believe inspiring readers about homesteading, self sufficiency

One comment

Pingback: How To Build The King Of DIY Fly Traps